Our Products

Innovative solutions for industrial testing and manufacturing needs

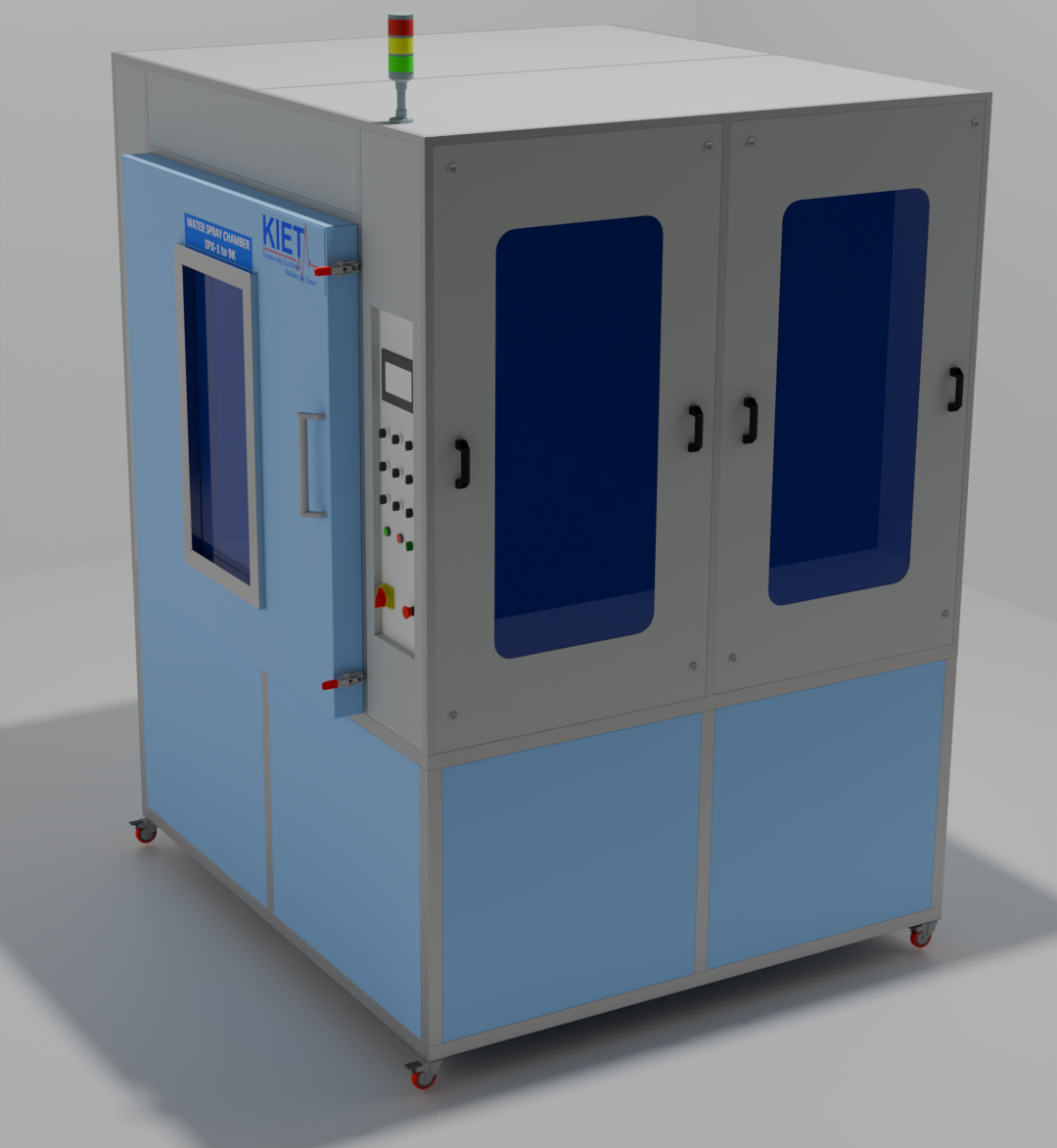

WATER SPRAY CHAMBER (IPX1 to IPX9K)

Controlled environmental testing system for evaluating water ingress protection of electrical and mechanical components as per international IP standards. Simulates dripping, spraying, splashing, high‑pressure jetting, and high‑temperature sprays to ensure reliability and compliance.

The Water Spray Chamber (IPX1 to IPX9K) recreates realistic water exposure scenarios to validate product sealing and durability. It covers vertical and tilted dripping, directional sprays and splashes, high‑pressure jets, and high‑temperature water spray profiles. The chamber enables pre‑production and dispatch‑stage verification for robust, compliant product releases.

Benefits:

- Ensures product compliance with IPX1 to IPX9K protection standards.

- Detects water ingress, sealing failures, and design weaknesses.

- Improves product reliability under real-world environmental conditions.

- Supports validation of enclosures, seals, and cable entries.

- Prevents field failures caused by water exposure.

- Suitable for EOL testing and quality assurance applications.

- Provides repeatable and controlled test conditions.

- Enhances customer confidence and reduces warranty risks.

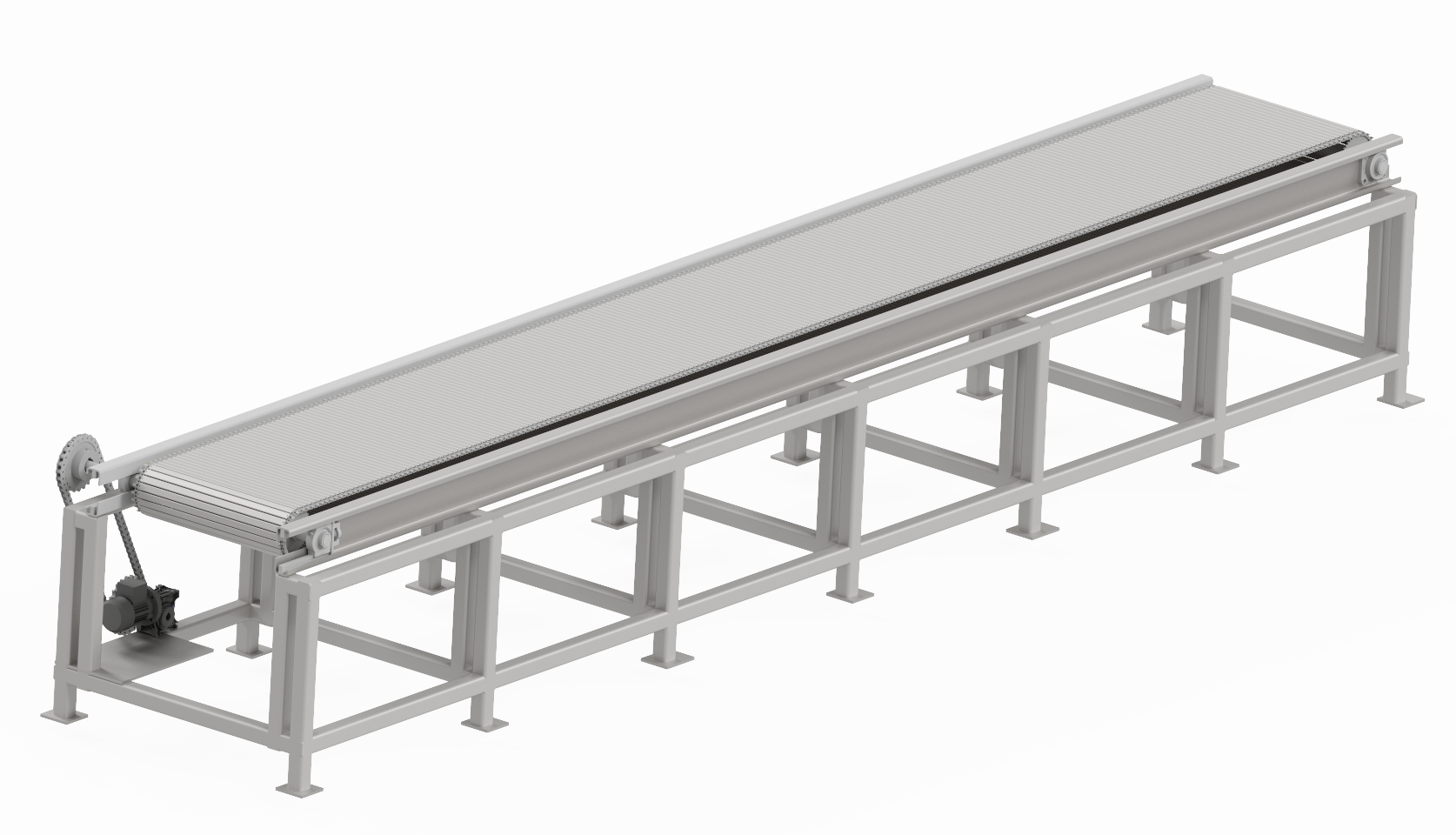

STRIP CONVEYOR

A Strip Conveyor is a material handling system designed to transport components, strips, or assemblies smoothly between stations in a production or testing line. It ensures controlled movement, proper orientation, and consistent spacing of parts, making it ideal for automated and semi-automated manufacturing environments. The system is engineered for reliable operation, low maintenance, and seamless integration with downstream processes.

Benefits:

- Ensures smooth and continuous transfer of components between stations.

- Maintains consistent part orientation and spacing during movement.

- Improves production efficiency by reducing manual handling.

- Minimizes component damage through controlled speed and stable support.

- Supports integration with EOL testing machines and assembly lines.

- Enhances operator safety and ergonomic working conditions.

- Allows flexible layout configuration for different line requirements.

- Reduces cycle time and increases overall throughput.

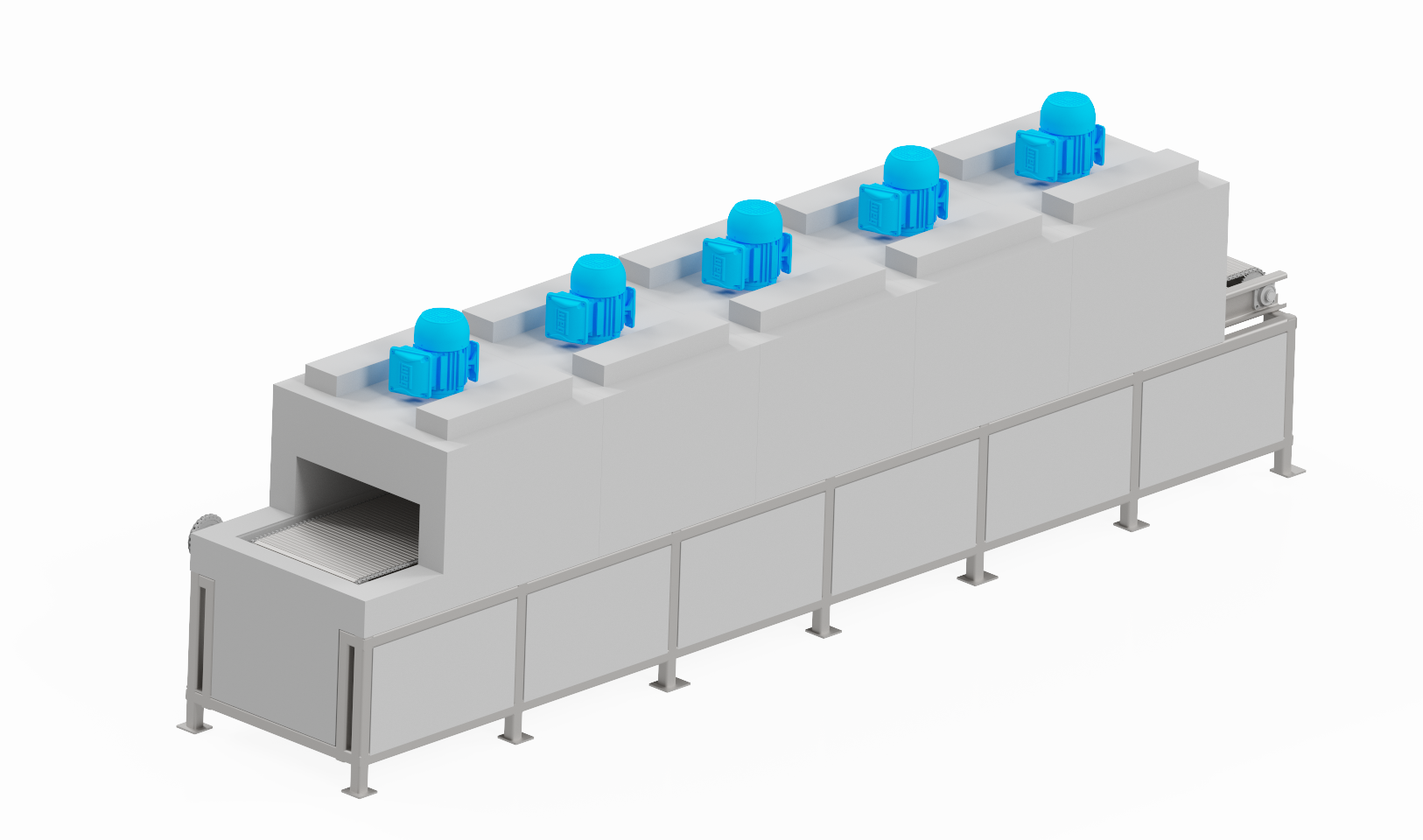

CURING CONVEYOR

A Curing Conveyor is a controlled-process material handling system designed to transport components through a defined curing zone where heat and time are applied to achieve proper curing of adhesives, coatings, resins, or insulation materials. It ensures uniform exposure, consistent dwell time, and stable process conditions, making it ideal for automotive, EV, and industrial production lines.

Benefits:

- Ensures uniform and controlled curing across all components.

- Maintains consistent dwell time for reliable process results.

- Improves bonding strength and coating quality through controlled heating.

- Reduces defects such as incomplete curing or uneven finish.

- Enhances production efficiency with continuous and automated operation.

- Supports integration with EOL testing and assembly lines.

- Improves product durability and long-term performance.

- Reduces rework, scrap, and warranty-related issues.

ROLLER CONVEYOR

A Roller Conveyor is a material handling system designed to transport components, assemblies, or pallets efficiently between workstations using a series of rollers. It provides smooth, stable movement with minimal effort and is ideal for production, assembly, inspection, and EOL testing lines. The system can be gravity-driven or motorized, ensuring flexibility for various industrial applications.

Benefits:

- Enables smooth and stable movement of components between stations.

- Reduces manual handling and improves operator ergonomics.

- Supports heavy and bulky loads with reliable roller construction.

- Improves line efficiency by enabling continuous material flow.

- Easily integrates with assembly, inspection, and EOL testing systems.

- Offers flexible configuration for straight, curved, or modular layouts.

- Requires low maintenance and provides long service life.

- Enhances workplace safety by minimizing lifting and handling risks.

LASER MARKING MACHINE

Laser marking systems are advanced machines that use focused laser beams to permanently mark or engrave surfaces with high precision, speed, and durability. They are widely used in industries like automotive, electronics, medical devices, and packaging due to their ability to create clear, wear-resistant marks without physical contact.

Features:

- High precision – ensures QR codes are scannable even at very small sizes

- Permanent durability – resistant to abrasion, heat, chemicals, and fading

- Non-contact process – no physical wear or damage to product surfaces

- Versatility – works on metals, plastics, ceramics, glass, and coated surfaces

- High speed – suitable for inline production and mass manufacturing

- Customization – supports serial numbers, batch IDs, and encrypted data in QR codes

- Traceability – enables product identification and supply chain compliance

- Eco-friendly – no inks, solvents, or consumables required

- Integration – compatible with automated production lines and databases

- Security – difficult to tamper with or counterfeit compared to printed labels

HIGH PRESSURE LEAK TEST MACHINE

A high-pressure leak test machine is a specialized system designed to detect leaks in industrial components by subjecting them to controlled high-pressure conditions. These machines ensure product reliability, safety, and compliance in industries like automotive, aerospace, railways, and defense. They combine automation, precision, and durability to deliver repeatable and accurate leak detection.

Features:

- Wide pressure range – operates from low to very high pressures (up to 250 bar or more)

- Advanced control system – PLC-based automation with touchscreen HMI for easy operation

- Multiple test modes – static leak detection, pressure hold, stepwise pressure profiling, real-time monitoring

- High accuracy & repeatability – detects even micro-leaks with precision

- Safety features – built-in interlocks, alarms, and pressure relief systems

- Automation & integration – compatible with production lines for continuous testing

- Durability & reliability – premium components ensure long service life

- Versatility – suitable for pipes, valves, tanks, castings, and other industrial components

- Data logging – records test results with graphs and reports for quality assurance

- Eco-friendly – uses air, gas, or helium without consumables like inks or chemicals

WATER BATH SYSTEM

A Water Bath System is a controlled temperature testing setup used to immerse components in water for functional testing, leak testing, thermal conditioning, or endurance validation. It ensures uniform heat transfer and stable test conditions, making it ideal for quality verification in production and R&D environments.

Benefits:

- Ensures uniform and controlled temperature exposure for accurate testing.

- Detects leakage, sealing failures, and structural defects at an early stage.

- Improves product reliability through thermal soaking and endurance testing.

- Supports quality and safety compliance for pressure-tested or sealed components.

- Provides stable and repeatable test conditions, reducing variation.

- Suitable for integration with EOL testing stations and automated lines.

- Enhances process validation for components exposed to thermal stress.

- Reduces rework, warranty issues, and field failures through effective screening.

.jpeg)

Buckle Durability Machine

SPM (Special Purpose Machine) for buckle testing are custom-engineered systems designed to evaluate the durability, strength, and performance of buckles under simulated stress conditions. These machines ensure product reliability and compliance with safety standards.

Benefits :

- Ensures buckle safety and compliance with industry standards.

- Identifies mechanical weaknesses before mass production.

- Improves product reliability through fatigue and cycle testing.

- Supports design validation and material selection.

- Automates testing for high-volume production environments.

- Provides traceable data for quality assurance and certification.

- Customizable for different buckle types and test protocols.

- Reduces warranty claims and enhances brand reputation.

LABORATORY HOT AIR OVEN

An LABORATORY Hot Air Oven is a temperature-controlled heating system used for drying, curing, preheating, and thermal processing of components and assemblies. It ensures uniform heat distribution through forced air circulation, making it suitable for automotive, EV, electrical, and industrial manufacturing applications. The oven is designed for consistent performance, energy efficiency, and reliable operation in production environments.

Benefits:

- Provides uniform and controlled heating for consistent process results.

- Ensures effective drying, curing, and preheating of components.

- Improves product quality by eliminating moisture and thermal variations.

- Supports precise temperature control for repeatable operations.

- Enhances production efficiency with stable and reliable heating cycles.

- Integrates easily with conveyors or manual loading systems.

- Reduces defects, rework, and process inconsistencies.

- Ensures safe operation with built-in temperature and safety controls.

Explore Our Product Range

Precision Machining Components

High-accuracy machined components for demanding industrial applications.

Learn More